Resources

Why chose MCBF ? The secret !

Made to measure quality

What makes MCBF different than any other manufacturer of carbon brush is the subject of impregnating for carbon brushes with very selected special materials for the electro-graphite grades plus using metal copper blocks manufactured by Hot pressed technology and not cold pressed as other suppliers. That is the secret behind the great performance of MCBF carbon brushes with quality second to none.

Uniqueness!

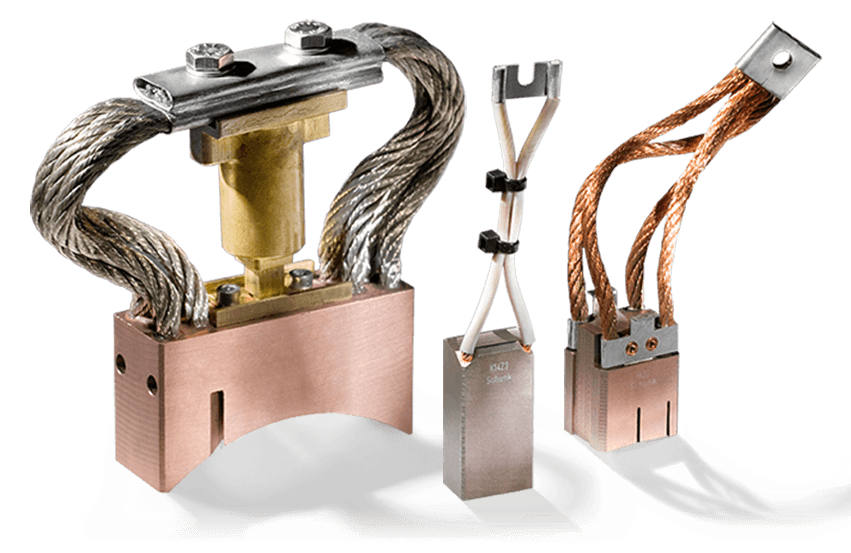

Explore our unique quality for metal copper grades

Hot Pressing This process allows the production of highly metal carbon graders with an optimal structure. Carbon brushes, hot pressed, are especially suitable for high currents and for very high load densities. We, MCBF, pride our self as the only manufacturer in the region of such carbon grades which are produced in this special hot pressing process.

Major characteristics and advantages of MCBF carbon brushes

- Optimum performance with long lifetime (Durability) comparing to any other manufacturer.

- Very low commutator or slipring wear out

- Large under or over loads ability

- Low sensitivity regarding atmospheric impact and conditions

- No swelling grades inside holders

- Impregnated grades with special materials

- Special modifications for carbon brushes based on operating conditions of the motors.

Main Carbon Brush Grades

Hard grades made from amorphous (retort coal, carbon black, coke) have a robust cleaning and long wearing characteristic. Normally used on commutators with flush mica and partially even with undercut mica. Grades with high electrical resistance and graphite structure are used for difficult commutation and a high circumferential speed.

Application:

fractional H.P motors, electrical tools, domestic machines, up to 30 KW and up to 500 V, contacts and current collectors.

Carbon graphite brushes consist of various graphite and carbon materials, having weak grinding effect due to mineral ingredients. Mica must be undercut. The brush is able to bring off burnt spots on the commutator, whilst speed and brush fire are law.

Application:

machines with high speed, for turbo-alternator sliprings and D.C machines, micro motors, fractional H.P motors and dynamos.

High resistance, high transit voltage and large ratio of vertical and horizontal resistance, all facts which influence favourably the suppression of commutating currents. Application:

Application:

schorch and Schrage type A.C commutator motors, D.C. up to 30 KW Auxiliar brushes for cross-field exitation, 3-phase commutator machines, repulsion motors, converters, fractional h.p motors, thyristor controlled motors, etc.

Made from pre-graphitized carbon material and converted into electro-graphite under temperature of about 2500 C for a prolonged period, thus feed from most impurities. The physical data such as resistance, density, strength etc. are more favourable than those of hard grades. It has further more good commutation, consumption and short circuit proof features. Mica must be undercut.

Application:

A.C and D.C motors, 3 phase commutators, traction motors, rotary phase converters, sliprings, arc welding, fractional h.p motors, control dynamos.

Made from graphite and other carbons by adding cooper and other metal powder. Excellent conductivity and low voltage drop. The current density is essentially higher than with graphite brushes.

Application:

earthing brushes, D.C low voltage machines, starters, sliprings (exiters), synchronised asynchronous motors, sliding contact line, etc.

The manufacture is equivalent to that of metal grades.

Application:

contacts, transmission of testing currents, micro motors of low voltage, tachometers etc.